GL-500H decoiler and straightener combo machine for thick metal strip feeding

- group name

- 2 in 1 Uncoiler Straightener

- Min Order

- 1 piece

- brand name

- HongEr

- model

- GL-500H

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 25 Apr 2019 17:41:04 GMT

Paramtents

Function decoiling and straightening combo machine

Feature uncoiler and leveller

Name coil unwinding and flating machine

Compact press and feeder machine

Usage coil sheet decoiling and straightening machine

attribute straightener uncoiler for thick steel sheet

Packging & Delivery

-

Min Order1 piece

Briefing

2 in 1 decoiler and leveller for handling metal sheet coil with thickness from 0.5-4.5mm with servo feeder for stamping line

Detailed

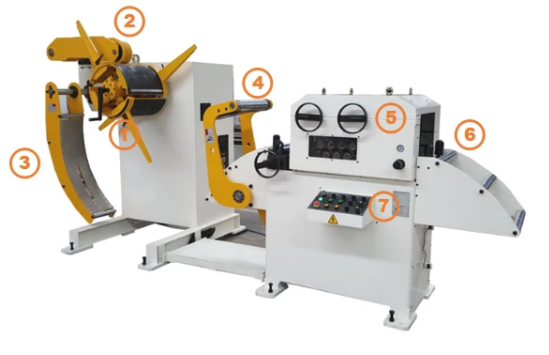

GL-500H Uncoiler And Straightener Combo Machine For Metal Coil Feeding Line

GL-500H is the type of combined decoiler and straightener machine. The equipment can decoiling and straightening sheet metal with the thickness 0.5mm to 4.5mm.

With pneumatic pressure on straightener roller and worm gear adjusting, it can achieve presicion straightening for many kinds of material.

The combined structure can make better synchronization of decoiling and straightening and save more work space.

Description

Decoiler Section

1, Decoiler with hydraulic expansion and the surface is treated by blackening;

2, Pressing arm to press coil;

3, Supporting arm with pneumatic to lift coil and the induction pole to help feed speed controlling;

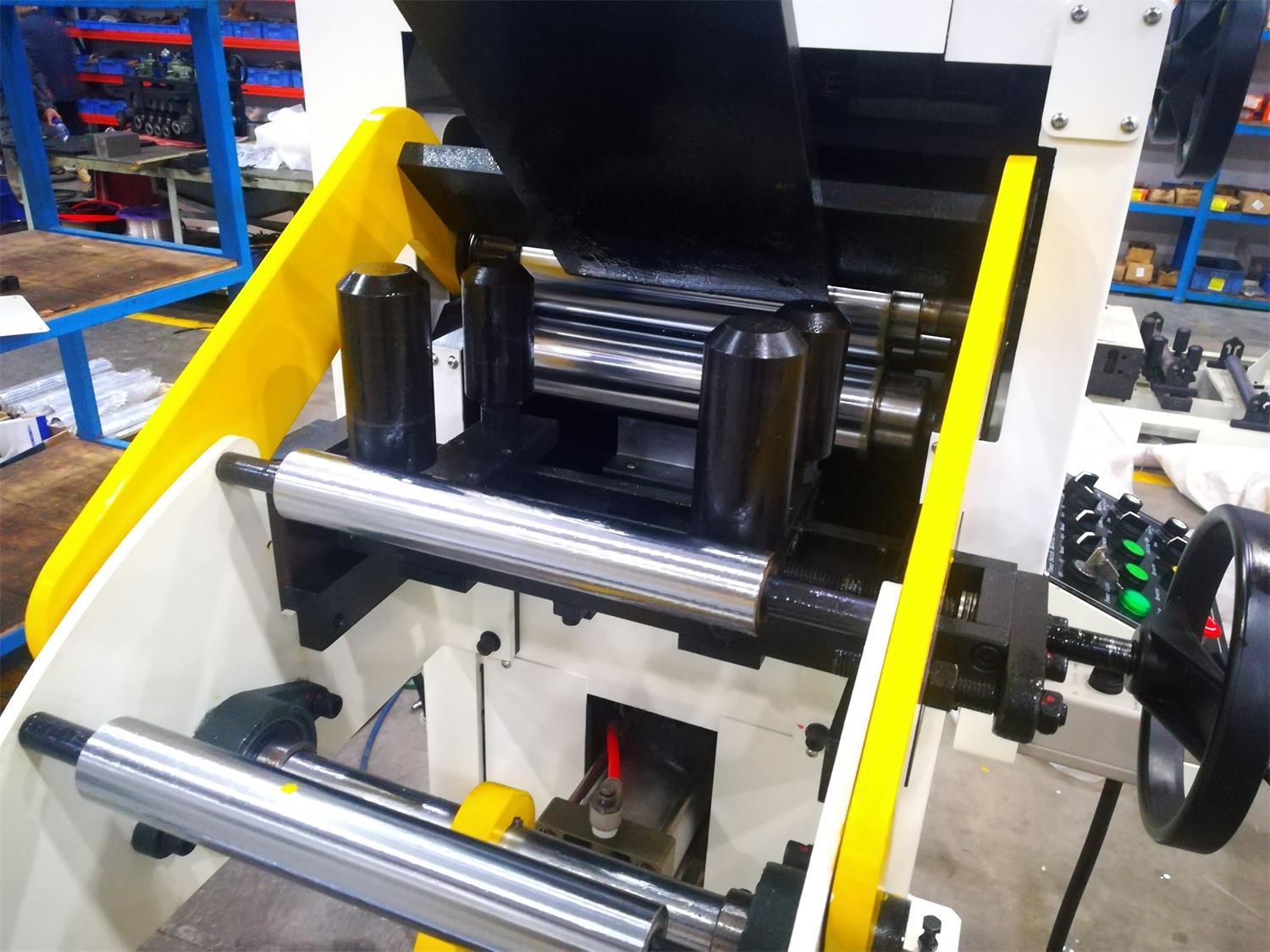

4, Coil inlet arm to make the coil into the feeding inlet easily;

5, Hand wheel to control the stop rollers which can allocate the strip. Worm & gear adjustment to adjust the gap between straightener rollers, which makes the operation easier and more precision performance;

6, Feeder outlet with cambered shape to make the coil strip go into the feeder machine easily;

7, Control systerm;

Specification

Model |

GL-300H | GL-400H | GL-500H | GL-600H |

Coil width(mm) | 300 | 400 | 500 | 600 |

Coil thickness(mm) |

0.5-4.5(6.0) |

|||

Coil weight(kg) | 2000 | 2000 | 3000 | 5000 |

Coil I.D(mm) | 460-520 | |||

Coil O.D(mm) | 1200 | |||

Speed(m/min) |

15 |

|||

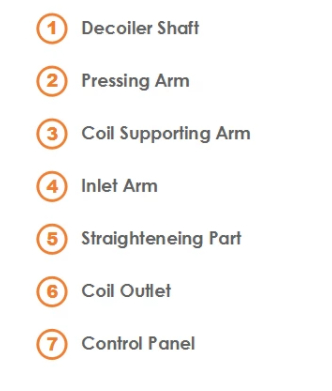

Straightener roller |

4 on top / 3 on bottom Bottm rollers have drive function |

|||

Pinch roller | Inlet: 2 / Outlet: 2 | |||

Straightener motor(KW) | 2.2 | 2.2 | 4.4 | 4.4 |

Uncoiler motor(KW) | 1.5 | 1.5 | 1.5 | 2.2 |

Mandrel expansion | Manual Expansion (Hydraulic for optinal) | |||

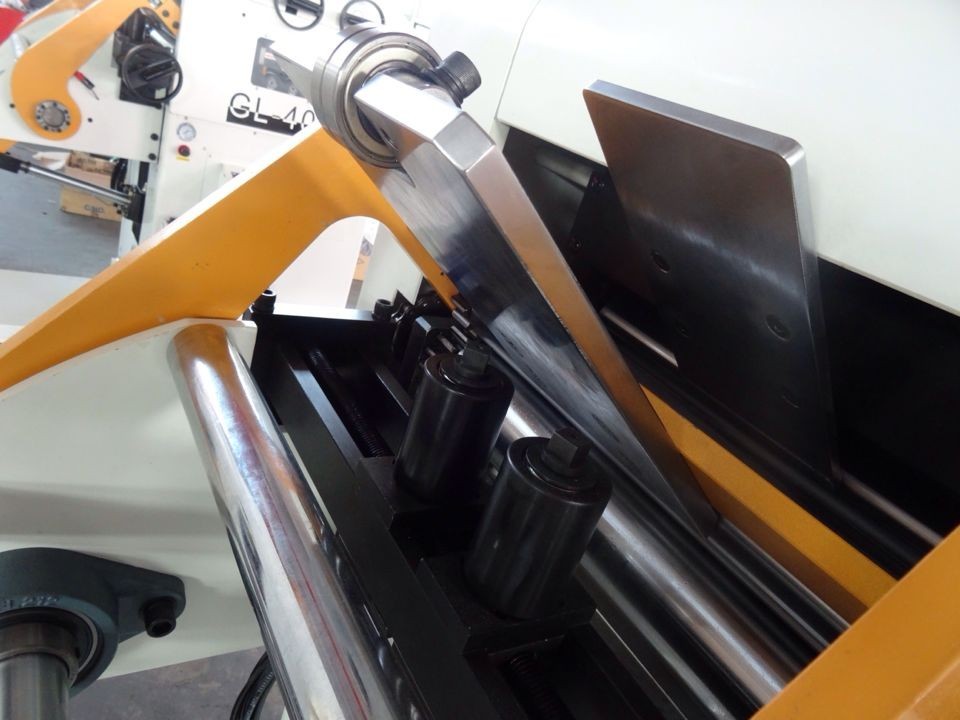

Detail Photo Show

Application

GL-500H thick coil decoiler and straightener combo machine is widely used in metal stamping line with thickness from 0.5-4.5mm. It is suitable for the stamping of electric appliance, construction, furniture industry, clothing metal parts, auto parts etc.

GL-500H

exported to Dubai

Metal stamping solution suggestion:

GL-H+ NC Servo Feeder + Press

GL-H

GL-500H decoiler and straightener conbo machine

exported to Indonesia.

Metal stamping solution suggestion:

GL-H+ NC servo feeder + Press

Solution Application

GL-H decoiler and leveller combo machine is popular in electric appliance, construction, furniture industry, clothing metal parts, auto parts stamping etc.

Package & Delivery

What we do

With 16 years of continuous research and practice in press feeding line manufacturing, HongEr Machine are growing as one of China's competitive manufacturer in the metal working market.

HongEr have a strong design and technology team and have a strict quality control system. Our machines(decoiler, leveller, feeder and press) are expored to many countries in north America, European, south Asia and Africa, etc.