GLK4-600 For 600mm Metal Strip Feeding In Punching Line Compacted With Power Press Machine

- group name

- GLK4 3 in 1 Coil Feeder for Press

- Min Order

- 1 piece

- brand name

- HongEr

- model

- GLK4-600

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 27 Jun 2019 17:22:26 GMT

Paramtents

Function unwinding straightening

Feature with coil car loading metal sheet

Name decoiler straightener auto feeding

Compact pressing machine

Usage auto metal parts stamping

attribute 3 in 1 servo feeder machine

Packging & Delivery

-

Min Order1 piece

Briefing

3 in 1 unwinder straightener feeder with press for metal steel coil punching, suits for metal coil in thickness 0.6-6.0mm.

Detailed

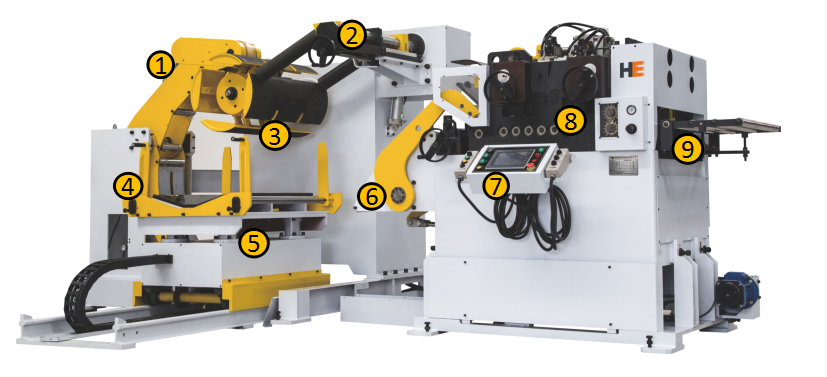

GLK4-600 For 600mm Metal Strip Feeding In Punching Line Compacted With Power Press Machine

Description

1, Pressing arm: with pneumatic power. Especially the PU pressing roller is with motor drive.

2, Limited arm: by hand wheel control.

3, Decoiler mandrel: hydraulic expansion.

4, Supporting arm: support the metal steel sheet coil, so as to protect the uncoiler mandrel.

5, Coil car: rubber cushion for non-slip when loading the metal coil.

6, Inlet feeding arm: clamp the metal strip and feeding it into straightener (leveler) smoothly.

7, Control display screen: operate the coil feeder machine with electrical control.

8, Straightener: straightener rollers are adjusted by worm and gear.

9, Outlet: outlet for strip feeding out.

specification

Model |

GLK4-600 |

|||||

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||||

Coil width(mm) |

70-600mm |

|||||

Coil thickness | 0.6-6.0mm | |||||

Coil weight | 5000kg | |||||

Coil I.D.(mm) |

480-520mm |

|||||

Coil O.D.(mm) |

1500mm |

|||||

Max. speed | 16-24 m/min | |||||

Feeding accuracy | +/- 0.15 mm | |||||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||||

Power | 380V 60HZ | |||||

Expansion | Hydraulic | |||||

Pressing arm | Pneumatic Type | |||||

Servo motor | AC7.5 | |||||

Uncoiler motor | AC2.2 | |||||

Features

3 in 1 decoiler straightener feeder machine:

1, full automation function

2, decoiling straightening feeding metal coils

3, suitable for metal steel like low carbon steel, high carbon steel, cold rolled steel, hot rolled steel

4, handle with heavy duty metal coils

5, easily operating with control panel

6, decoiler straightener and feeder are controlled by the same signal, so as to make high synchronous

7, without second deformation ( compared with single machine, there is a loop between straightener and feeder)

8, save work space

9, save labor cost

10, compact with progressive mold for metal stamping to increase production capacity

Application

GLK4 unit servo coil feeder

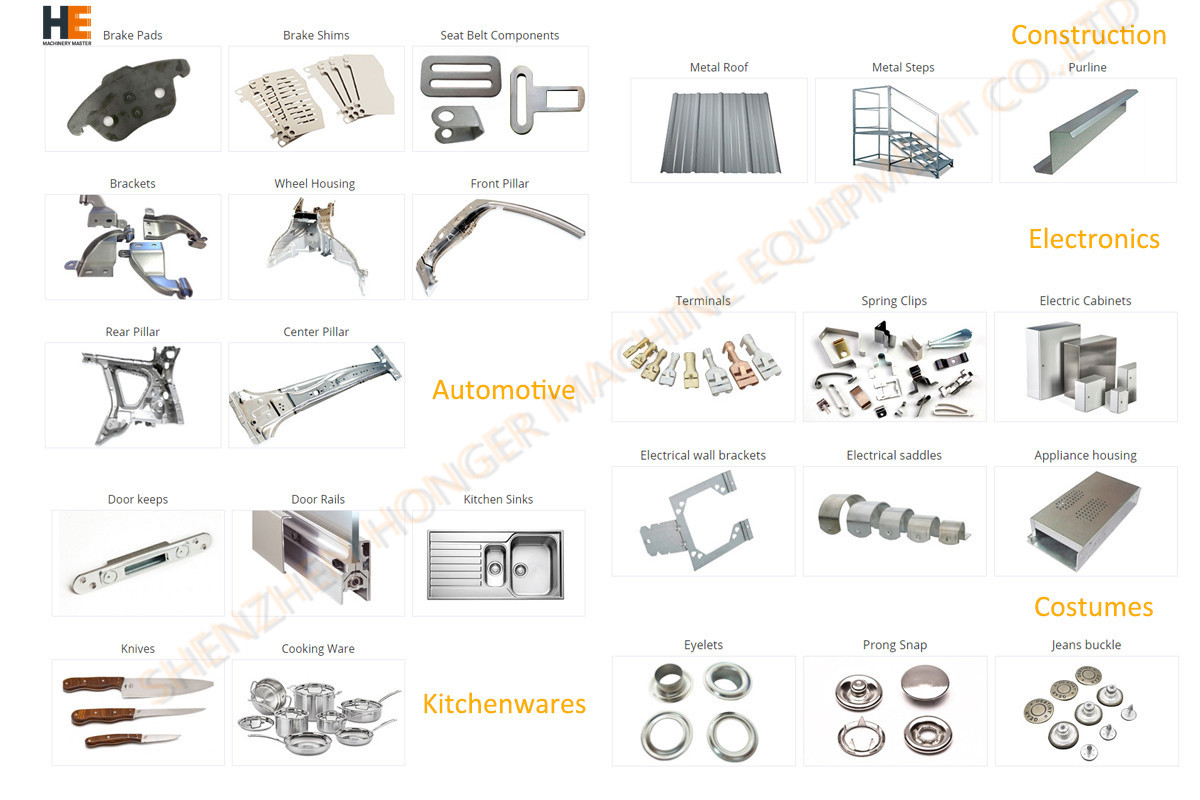

GLK4 3 in 1 coil feeder machine is combined with decoiler, straightener, feeder for automation feeding in metal stamping line.

It is popular in electric appliance, construction, furniture industry, automotive stamping.

This 3 in 1 servo coil feeder machine can be equipped with power press or hydraulic shearing for blanking.

GLK4

uncoiler, straightener, feeder

compacted with 250 ton AIDA press

working for automotive stamping

in automobile manufacture in UK

Solution Sugeestion:

3 in 1 decoiler straightener feeder + press

Package & Delivery