GLK2 3 in 1 Turnkey Integration System Combined Metal Coil Decoiler Straightener Feeder for press

- group name

- GLK2 3 in 1 Coil Feeder for Press

- Min Order

- 1 piece

- brand name

- HongEr

- model

- GLK2

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Wed, 06 Mar 2019 16:59:49 GMT

Paramtents

Function auto decoiler straightener feeder

Feature metal coil feeder handling

Name Turnkey Uncoiler straightener feeder 3 in 1

Compact with metal press machine

Usage metal steel decoiling feeding for stamping

attribute 3 in 1 auto decoiler straightener feeder

Packging & Delivery

-

Min Order1 piece

Briefing

3 in 1 auto decoiler straightener feeder compact with press for metal stamping, suits for metal coil in thickness 0.3-3.2mm.

Detailed

GLK2 Decoiler Straightener Feeder Machine for Steel Sheet Metal Coil Handling

Photo show

Description

1, Coil car

Hydraulic power,wear-resisting surface

2, Decoiler Mandrel

Hydraulic expansion, delta inverter

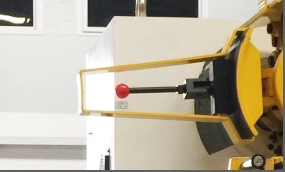

3, Pressing Arm

Coil well-knit, no disperse

4, "A" frame

Locating coil, avoid coil shuffling

5, Coil Inlet

Supporting arm for optional

5, Coil Inlet

Supporting arm for optional

6, Control Board

Weinview touchscreen

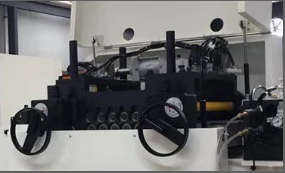

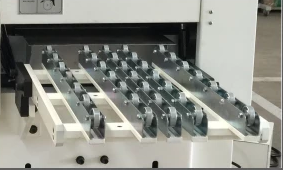

7, Straightening Part

11 pcs GCr15 straightener rolls

8, Hand wheel

Precision straightening value adjustment

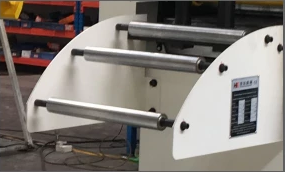

9, Outlet Support Bracket

Adjustable in length

10, Optional Lubrication Unit

Automatic lubrication control, 20L

11, Servo System

Yaskawa servo motor and servo drive

specification

Model |

GLK2-400 | GLK2-500 | GLK2-600 | GLK2-800 |

GLK2-1000 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum, etc. | ||||

Coil width(mm) |

50-400 | 50-500 | 50-600 | 50-800 |

50-1000 |

Coil thickness | 0.3-3.2mm | ||||

Coil weight | 3000kg | 5000kg | 7000kg | ||

Coil I.D.(mm) |

480-520 |

||||

Coil O.D.(mm) |

1200 |

||||

Max. speed | 20 m/min | ||||

Feeding accuracy | +/- 0.1 mm | ||||

Straightener Rolls | Φ48mm * 11pcs | Φ68mm * 7pcs | |||

Pinch Rolls | Φ68mm * 2 pcs | Φ88mm * 2pcs | |||

Power | 380V 60HZ | ||||

Expansion | Hydraulic | ||||

Pressing arm | Pneumatic Type | ||||

Servo motor | 2.9 Kw | 2.9 Kw | 2.9 Kw | 4.5 Kw | 5.5 Kw |

Uncoiler motor | 1.5 Kw | 1.5 Kw | 2.2 Kw | 2.2 Kw | 3.7 Kw |

Application

GLK2 combined with uncoiler straightener feeder machine, maximumlly save the workspace, and make integration of the decoiling, straightening and feeding handling. The GLK2 combined machine is widely used in metal stamping line for AUTO industry, electric appliance, construction, furniture industry.

GLK2

GLK2

Package & Delivery