GLK2-1000 Combo Servo Coil Feeder Compact Seyi Press For Gree Air Conditional Shell Blanking

- group name

- GLK2 3 in 1 Coil Feeder for Press

- Min Order

- 1 piece

- brand name

- HongEr

- model

- GLK2-1000

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Wed, 12 Jun 2019 10:12:37 GMT

Paramtents

Function auto decoiler straightener

Feature Stamping for metal coil feeder

Name Uncoiler straightener feeder

Compact with metal press machine

Usage metal steel fabrication with stamping

attribute 3 in 1 decoiler straightener feeder

Packging & Delivery

-

Min Order1 piece

Briefing

3 in 1 decoiler straightener feeder compact with press for metal stamping, suits for metal coil in thickness 0.3-4.5mm.

Detailed

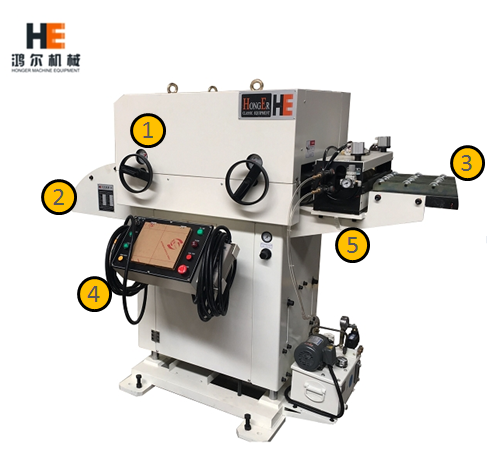

GLK2-1000 Combo Servo Coil Feeder Compact Seyi Press For Gree Air Conditional Shell Blanking

Description

Decoiler Section

1, Pressing arm to press coil;

2, PU wheel on the pressing arm, so as to protect the surface of coil;

3, "A" frame coil keeper to locate coil;

4, Decoiler mandrel with hydraulic expansion and delta inverter;

5, Supporting arm with pneumatic to lift coil;

Straightener & Feeder Section

1, Worm & gear adjustment to adjust the gap between straightener rollers;

2, Feeder inlet can be customized with coil inlet arm;

3, Outlet support bracket can be customized with the length;

4, Display screen is from Weinview Taiwan;

5, Oil car is optional which can protect the moulds;

specification

Model |

GLK2-300 | GLK2-400 | GLK2-500 | GLK2-600 |

GLK2-700 |

GLK2-800 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||||

Coil width(mm) |

50-300 | 50-400 | 50-500 | 50-600 |

50-700 |

50-800 |

Coil thickness | 0.3-3.2mm | |||||

Coil weight | 2000kg | 3000kg | 5000kg | |||

Coil I.D.(mm) |

480-520 |

|||||

Coil O.D.(mm) |

1200 |

|||||

Max. speed | 20 m/min | |||||

Feeding accuracy | +/- 0.1 mm | |||||

Straightener rollers | 6 rollers on top 5 rollers on bottom | |||||

Power | 380V 60HZ | |||||

Expansion | Hydraulic | |||||

Pressing arm | Pneumatic Type | |||||

Servo motor | AC1.8 KW | AC2.9 KW | AC4.4 KW | AC5.5 KW | ||

Uncoiler motor | AC1.5KW | AC2.2 KW | AC3.7 KW | |||

Features

GLK2 series 3 in 1 coil feeder machine:

1, decoiler expansion by hydraulic

2, pressing arm with PU roller to prevent metal coil from loose

3, supporting arm could be optional according to the coil weight

4, coil car is optional to insist metal coil loading

5, straightener and feeder are drove by servo motor

6, straightening with high performance with worm and gear adjusting

7, coil feeding accuracy with +/-0.1mm

8, straightener feeder rollers are electroplated with chrom to achieve surface hardness to HRC 60-62, which makes rollers more durable

9, with Mitsubish PLC system

10, touch screen is easily to operate and quick-learned

11, hydraulic shearing is optional to cut the metal coil head or for cut to length line

12, lubrication system is optional to protect stamping tooling

Package & Delivery