GLK3 Uncoiler Straightener Feeder Machine for Metal Fabrication

- group name

- GLK3 3 in 1 Coil Feeder for Press

- Min Order

- 1 piece

- brand name

- HongEr

- model

- GLK3

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Thu, 20 Dec 2018 16:33:30 GMT

Paramtents

Function servo roll feeder

Feature Servo Straightener Feeders

Name 3 In 1 straightener Feeder

Compact Coil Handling Equipment

Usage Automatic Feeding Equipment For Presses

attribute Sheet Metal Feeding Equipment

Packging & Delivery

-

Min Order1 piece

Briefing

3 in 1 uncoiler straightener feeder machine for coil feeding line in automotive stamping with press

Detailed

GLK3 Uncoiler Straightener Feeder Machine for Metal Fabrication

Description

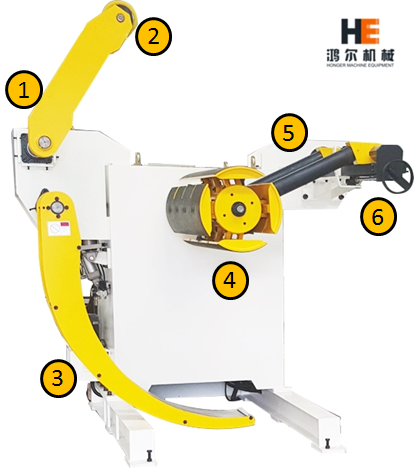

Decoiler Section

1, Pressing arm with pneumatic to press coil;

2, PU wheel on the pressing arm, so as to protect the surface of coil;

3, Supporting arm with pneumatic to lift coil;

4, Decoiler mandrel with hydraulic expansion and delta inverter;

5, Coil keeper with pneumatic to locate coil;

6, Hand wheel for centring adjustment.

Straightener & Feeder Section

1, Feeder inlet;

2, Coil inlet arm for coil feeding assistant;

3, Hand wheel to control the stop rollers which can allocate the strip;

4, Display screen is from Weinview Taiwan;

5, Worm & gear adjustment to adjust the gap between straightener rollers;

6, Outlet support bracket can be customized with the length;

Specification

Model |

GLK3-400 | GLK3-600 |

GLK3-800 |

GLK3-1000 |

Coil width(mm) |

50-400 | 50-600 |

50-800 |

50-1000 |

Coil thickness(mm) |

0.3-4.5 | 0.3-4.5 |

0.3-4.5 |

0.3-4.5 |

Coil weight(kg) |

3000 | 5000 |

7000 |

7000 |

Coil I.D.(mm) | 480-520 | |||

Coil O.D.(mm) | 1200 | |||

Feeding pitch(mm) | 0-500 | |||

Speed(m/min) | 16-24 | |||

Straightener roller(pc) | 4 on top / 3 on botton | |||

Feeding roller(set) | 1 | |||

Servo motor(KW) | AC4.4 | AC4.4 | AC5.5 | AC5.5 |

Uncoiler motor | AC2.2 | AC2.2 | AC3.7 | AC3.7 |

Expansion | Hydraulic | |||

Power(V) | 220/380 | |||

Operating Air(Mpa) | 0.49 | |||

Application

GLK3 decoiler straightener feeder is widely used in coil handling auto feeding line for metal parts stamping with press machine. It is popular in electric appliance, construction, furniture industry, automotive stamping, etc.

GLK3-400F

Customized GLK3

uncoiler straightener feeder machine

with coil car

compacted with Chin Fong press

for auto parts stamping

exported to UK

Metal stamping solution suggestion:

3 in 1 servo feeder + press machine

GLK3-600

GLK3 servo feeder machine

with coil car

compacted with large tonnage press

for metal stamping

exported to Indonesia

Metal stamping solution suggestion:

3 in 1 servo feeder + press machine

Package & Delivery